Pilot plant development for the next generation of H2O2 production using water, air, and green energy in a novel electrolyser and concentrator system

In Power2Hype we aim to establish a sustainable route for the hydrogen peroxide production. Based on air and water as feedstocks, and renewable energy as the sole energy source, the Power2Hype route addresses an economically viable and green alternative to the classical energy-demanding anthraquinone process

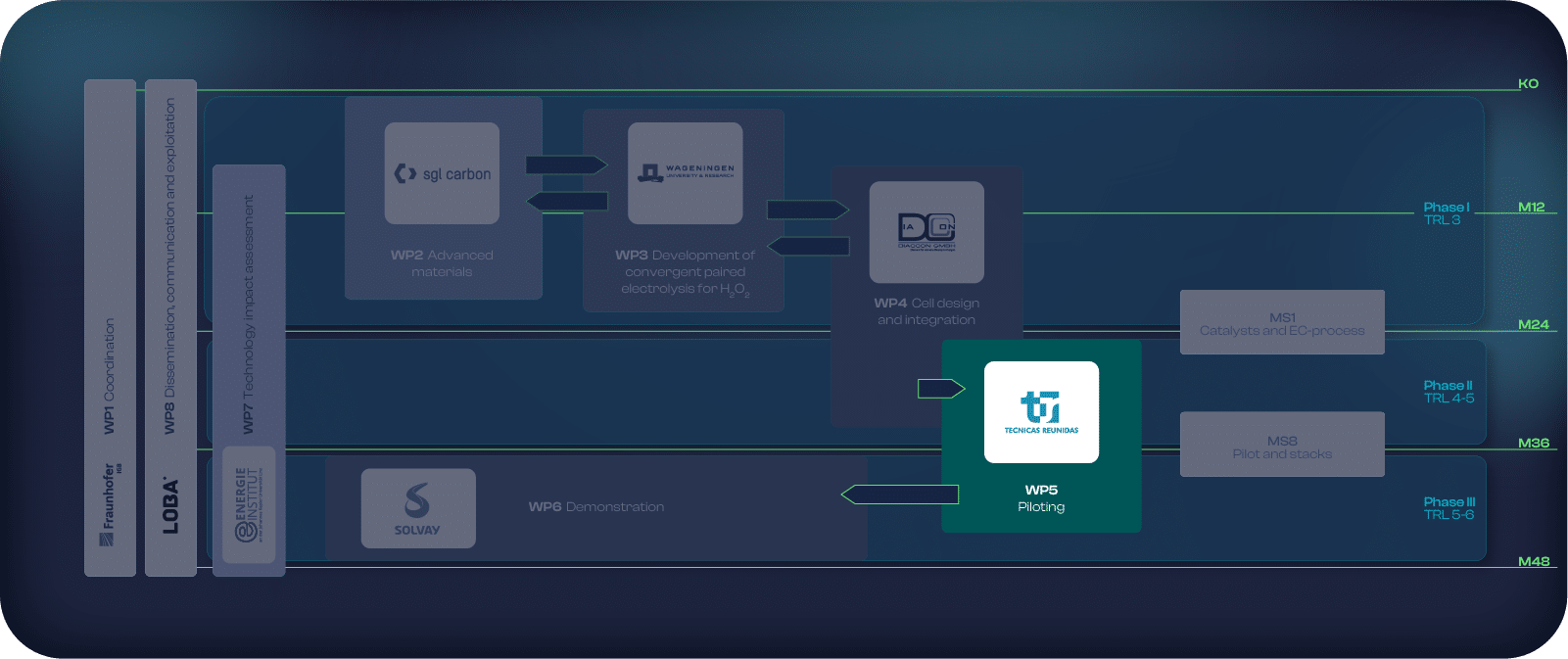

In work package 5 (Month 16-36), Tecnicas Reunidas, DiaCCon, Solvay, FHG, SolvGe and IRIS are focused on the design, production, installation, and commissioning of a pilot scale continuous flow demonstrator capable of producing up to 20 kilograms of H2O2/day in a relevant industrial environment. The prototype will be placed in a container to provide device mobility and decentralized operation. Demonstration will take place in Brussels (Belgium) at the Solvay’s Research and Technology labs (WP6).

In WP5 Tecnicas Reunidas will lead the upscale of electrochemical hydrogen peroxide production. DiaCCon will design electrolyser stacks, which represent a technological leap, meticulously designed to meet Power2Hype ambitious goals. Meanwhile Tecnicas Reunidas takes charge of the pilot plant design, collaborating with partners to craft a robust system based on insights from WP4 modelling. This extensive design covers operation modes, basic engineering, safety systems and much more.Simultaneously, IRIS drives the project into the digital age, undertaking the digitalization of the pilot plant. This involves developing an advanced monitoring and control system and creating a digital twin linked to the real-world case study. The innovative approach combines mechanistic modelling with real-time data acquisition.

In the final stages, Tecnica Reunidas oversees the construction, commissioning, and testing of the pilot plant. This includes the installation of DiaCCon’s electrolyser stacks, SolveGe’s separation unit and the implementation of IRIS’s monitoring and control system. Envision a mobile, modular system ready to reveal the future of decentralized H2O2 production. Power2Hype is at the forefront of this revolutionary journey!

WP5 has the key role of developing, building, commissioning and testing of a pilot plant. This facility is engineered to produce hydrogen peroxide from air, water and electricity. Serving as a comprehensive showcase, it elucidates the dynamics of the entire Power2Hype process and demonstrates the future of hydrogen peroxide production.