Fraunhofer IGB advances paired electrolysis for sustainable hydrogen peroxide production

As part of the Power2Hype project, the Fraunhofer Institute for Interfacial Engineering and Biotechnology (IGB) is driving the development of a sustainable and innovative approach to pair the cathodic and anodic production of hydrogen peroxide (H2O2).

While significant progress is being made on the cathodic H2O2 generation process by Wageningen Research, further developments are still on going to fully optimize this process. In this context, the anodic H2O2 production is a key step towards the paired electrolysis concept, which can promote a current efficiency of up to 200% by generating valued products in both cathodic and anodic half-cells simultaneously. Fraunhofer IGB is addressing the challenges associated with pairing these half-cells and optimizing the system for efficient and selective H2O2 generation. This work involves the use of specialized boron-doped diamond (BDD) anodes, developed in collaboration with Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) and DiaCCon GmbH (DIA).

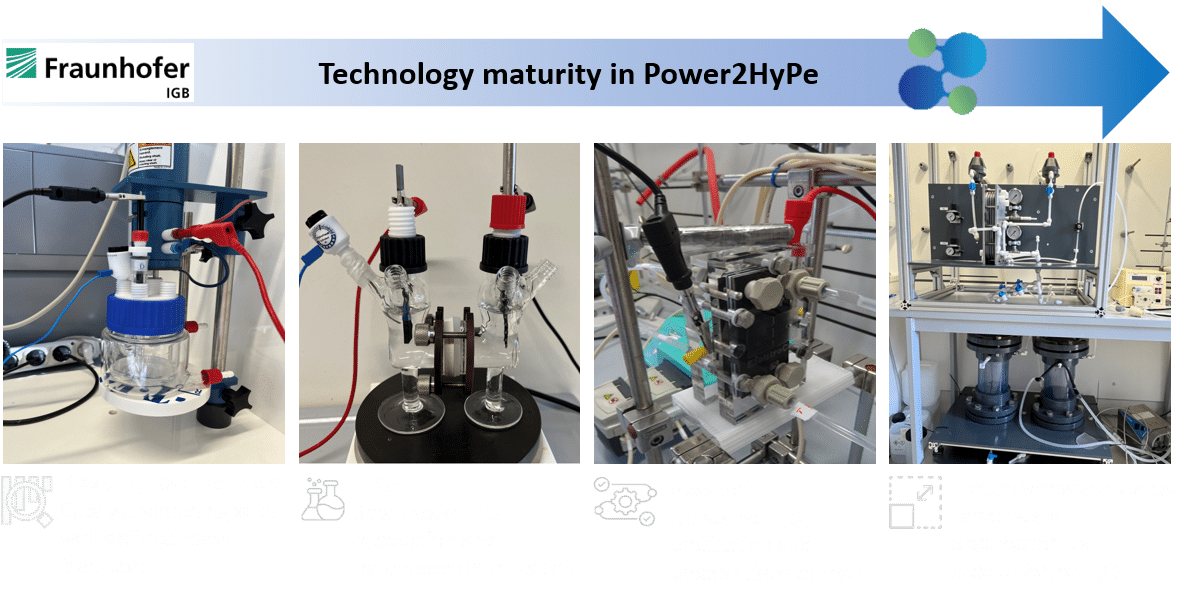

Ongoing research and development at Fraunhofer IGB team is investigating various operational parameters, including cell configuration, electrolyte composition, and current densities, alongside the modulation of BDD coating properties. The goal is to create a comprehensive database of parameters that will facilitate the transition of paired electrolysis from laboratory-scale experiments to industrial-scale applications. A key focus of the research is understanding the interaction between BDD material properties and operating conditions, particularly the role of electrolytes near the BDD electrode surface. This knowledge will set the foundation for future material design and process optimization.

A test station equipped with larger electrolyte reservoirs and high voltage power supply is being used for continuous operation of custom-designed electrolyzers in different scales.

Building on upcoming results from electrolyzer tests conducted at Fraunhofer IGB and Wageningen Research, and in close cooperation with the Power2HyPe project partners, Fraunhofer IGB will transition H2O2 production from the current semi-batch mode to a continuous and scalable electrochemical process. This development marks a significant step forward in increasing the technology readiness level of electrochemical H2O2 production.