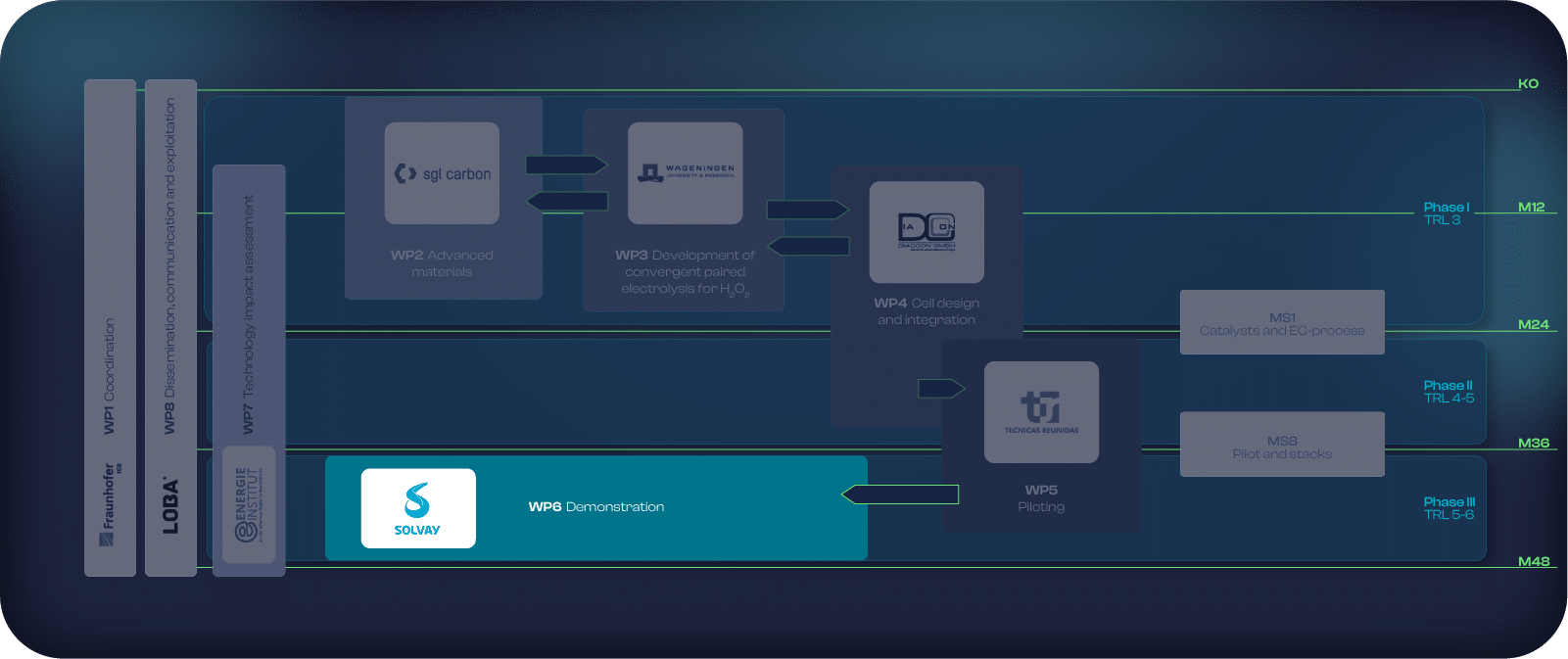

Demonstration of H2O2 Electrosynthesis at Pilot Scale

The primary objective of WP6 is to conduct a mid-scale pilot study to assess the feasibility, time, costs and scalability factors for the proper design and implementation of a full-scale commercial electrolytic hydrogen peroxide production process. The facility will be located at a Solvay site and is anticipated to have a production capacity of several kg of H2O2 per day with product concentrations ranging from diluted to 99%.

The implementation of the demonstrator will ensure the operability and lifetime of the components used in the process. In cooperation with Tecnicas Reunidas and SolvGE, a comprehensive safety risk assessment will precede system operation, utilizing a HAZOP methodology for proactive identification of procedural hazards at the specific operational site.

Following the safety assessment, the pilot plant will undergo continuous process operation with rigorous monitoring of key parameters. This operational phase will evaluate the system robustness and its adaptability to intermittent electrical grid loading, crucial for scenarios of remote locations where electrical supply is contingent upon the availability of renewable energy. A comparative analysis between the real demonstration and a digital twin will be conducted by IRIS.

The final product hydrogen peroxide will be validated for its industrial applicability, internally by Solvay, and in collaboration with external industrial partners as end-users.

WP6: Connecting theory to practical success. Our innovative approach in producing commercial hydrogen peroxide ensures a seamless transition from concept to industry reality.