Advanced Materials for electrochemical production of hydrogen peroxide

The vision of Power2Hype (P2H) is to establish a novel technology for producing hydrogen peroxide on industrial scale using a tandem electrolysis concept (electrochemical conversion to the desired product on both electrodes).

Anode 2H2O -> 2H+ + 2 e– + H2O2 E0 = + 1.76 V vs SHE

Cathode: O2 + 2H+ + 2e– -> H2O2 E0 = + 0.67 V vs SHE

This approach requires innovative and scalable materials and components for manufacturing of electrochemical reactors which can be operated at high conversion efficiency and selectivity. In the P2H project, we will develop all cell components with abundant materials only, to obtain an efficient and sustainable cell design with a zero-gap configuration.

Cathodes to be developed consist of porous carbon paper gas diffusion layers (GDL, provided by SGL) coated with carbon-based catalysts (provided by WUR) in order to perform the oxygen reduction reaction (ORR). The anodes will be based on BDD (provided by FAU) deposited on novel and low-cost substrates to perform the water oxidation reaction (WOR). Solvay will contribute with novel, non-fluorinated cation (CEM) and anion-exchange membranes (AEM).

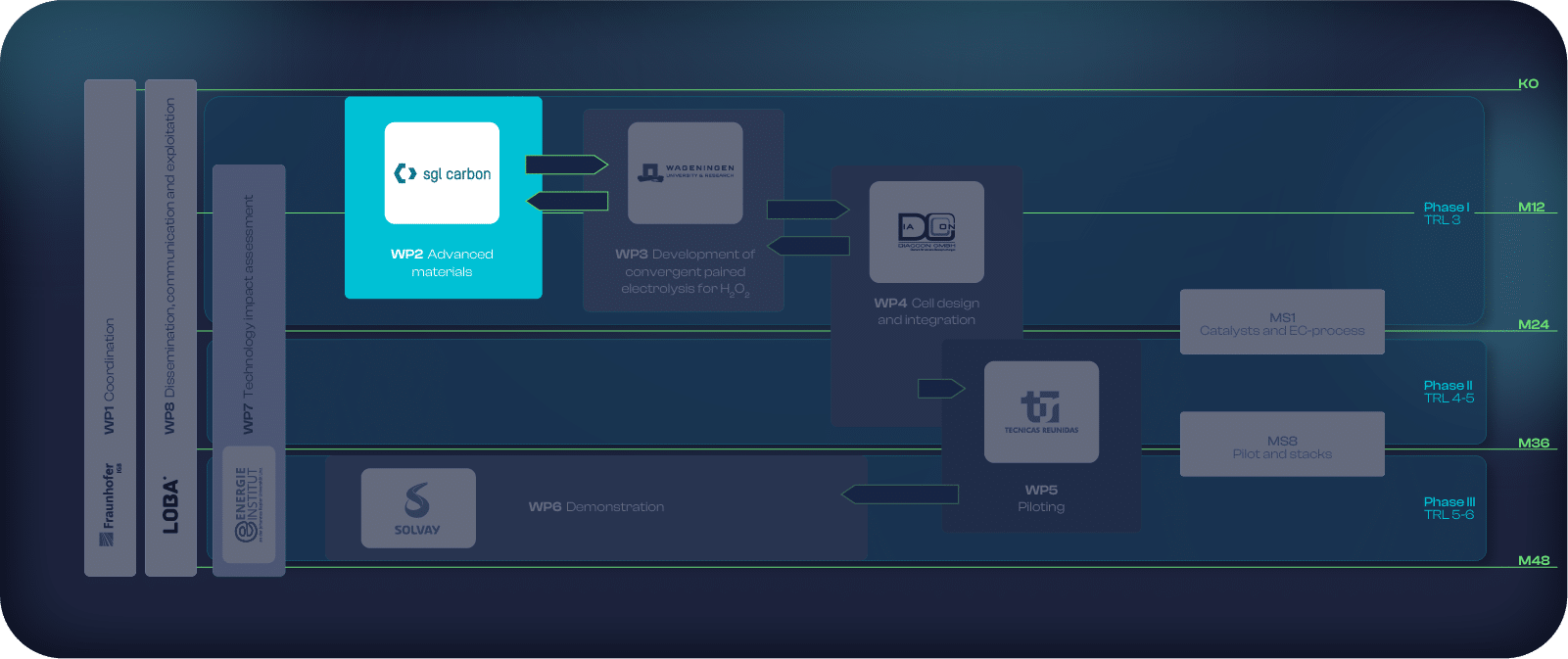

All material and component development is performed in close cooperation with work package 3 (paired electrolysis process development) and work package 4 (full scale electrolyser/system development).

WP 2 provides material advances for an efficient and industrially viable operation of paired electrolysis of oxygen and water to hydrogen peroxide.