Towards paired electrolysis by integration of the anodic and cathodic production of hydrogen peroxide

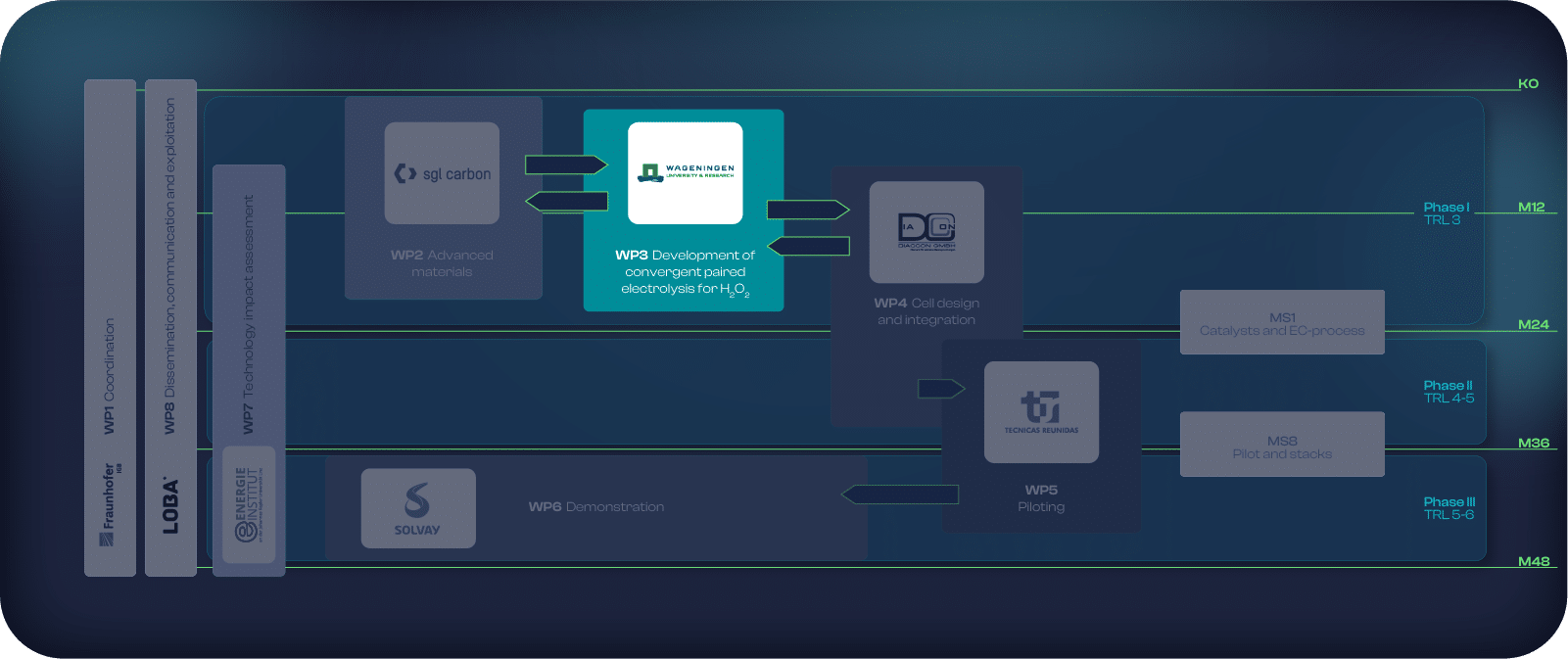

Power2Hype aims to use energy cost-effectively by utilizing electrons twice for the production of hydrogen peroxide. Hydrogen peroxide production is thus targeted at the cathode as well as the anode in a so-called paired 200% electrolyzer. WP3 deals with developing and efficiently coupling anodic and cathodic reactions to achieve an optimal convergent paired electrolysis for H2O2 production. Main partners contributing to this Work Package are Fraunhofer IGB (FH-IGB), Wageningen Food and Bio-based Research (WR) and Solvay

Currently, hydrogen peroxide is produced industrially via the energy-intensive anthraquinone oxidation process. To have a cost-competitive electrolytic process, several key performance indicators (KPI’s) have been set, which include current density, energy usage, faradaic efficiency and hydrogen peroxide concentration. Optimization of individual aspects of the electrolyzer is required to come to an optimized paired electrolytic process.

Therefore, first part of this work package (M6-M24) involves the optimization of individual half-cell reactions, which is performed by FHG and WR, where Solvay focuses on optimizing their Aquivion® polymer platform with the aim to provide anions and cations exchange membranes (AEMs and CEMs), and also investigate several formulation routes to design the porous solid porous electrolyte (PSPE) based on Solvay CEM materials.

An important aspect is the alignment of the reaction parameters and reactor configuration to enable optimal operation of the cathodic (WR) and anodic half-cell (FH-IGB) reaction in a paired configuration. Optimization of the electrolyzer is performed in close conjunction with work package 2, where new catalyst materials, electrodes, membranes and gas diffusion layers are developed; as well as with work package 4, where the electrolyser is scaled-up and down-stream processing is developed to obtain highly concentrated hydrogen peroxide solutions (20-99%).

Second part of this work package (M18-M30) involves integration of both half-cell reactions to enable paired electrolysis. FH-IGB, together with WR, will optimize the conditions for the paired electrolysis. Final step is the demonstration of the paired electrolyser under continuous and stable operation.

Empowering tomorrow’s industry: Power2Hype aims to produce hydrogen peroxide from renewable energy, water and air.